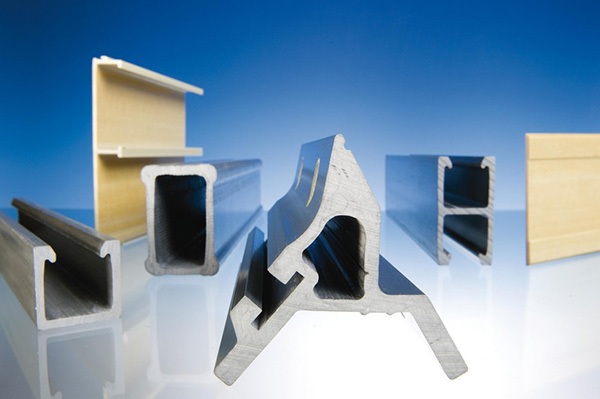

Pultrusion with polyurethane (PU) resins offers enormous potential for the efficient mass production of composite sections

The trailblazing developments in PU pultrusion by Covestro and distinguished partners, KraussMaffei and the Institute of Plastics Processing at RWTH Aachen University, are pushing the boundaries of what has been historically possible and paving the way for new sustainable applications for our customers.

Pultrusion is a manufacturing process enabling the continuous manufacturing of composite sections and can offer widespread applications, but only under the right circumstances. But we’ve only scratched the surface; there is so much more potential in pultrusion that can be explored in the future.

Process and machine technology advances combined with innovations in chemistry were needed to support industrial-scale manufacturing for market segments to achieve huge efficiency, cost, performance and environmental benefits but have so far been unable to adopt pultrusion.